Nanoksa G-Plus

Nanoksa G-Plus

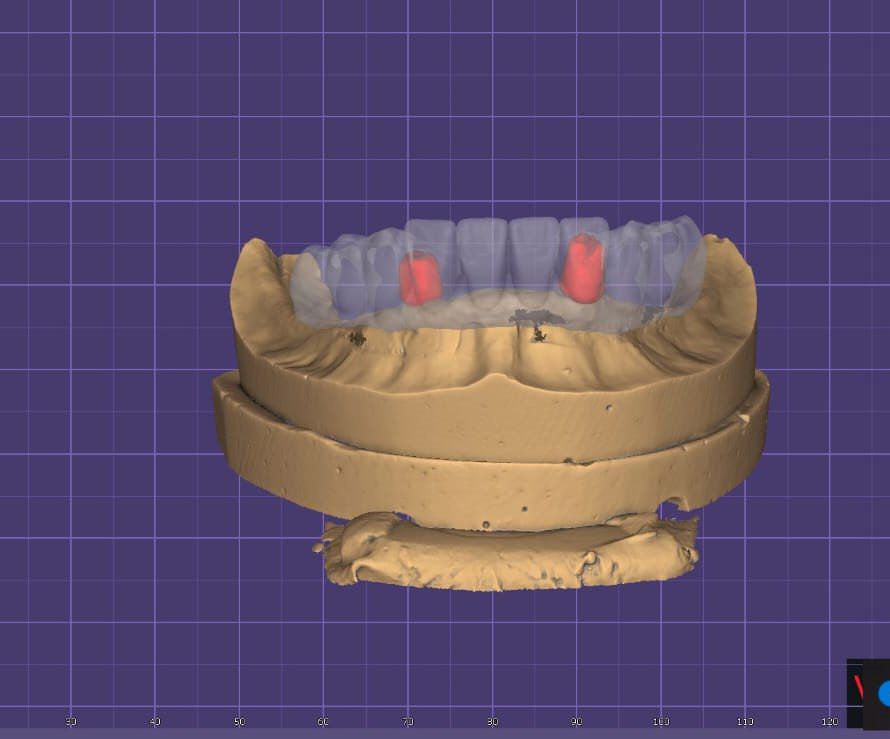

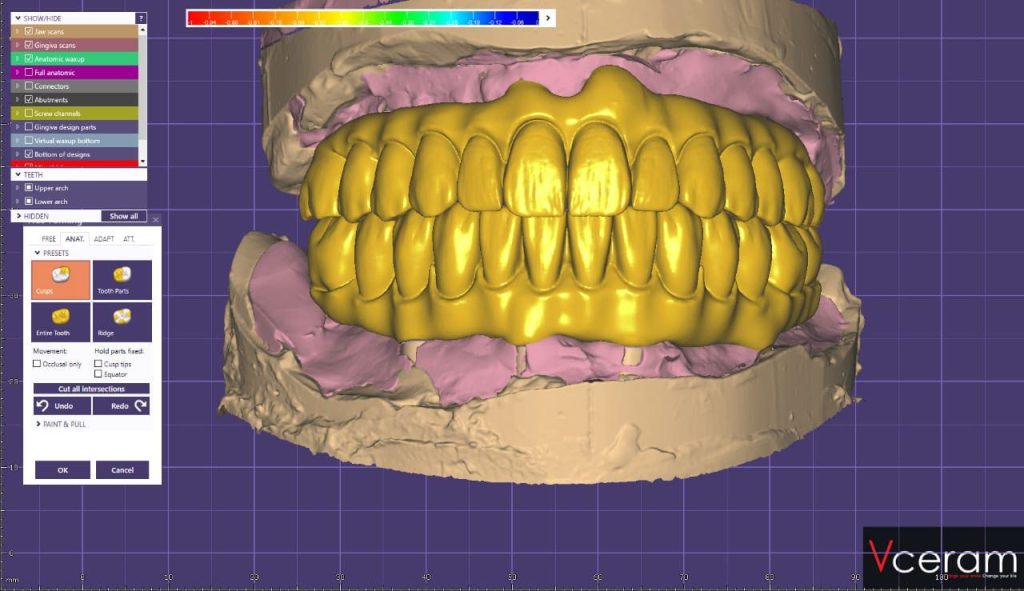

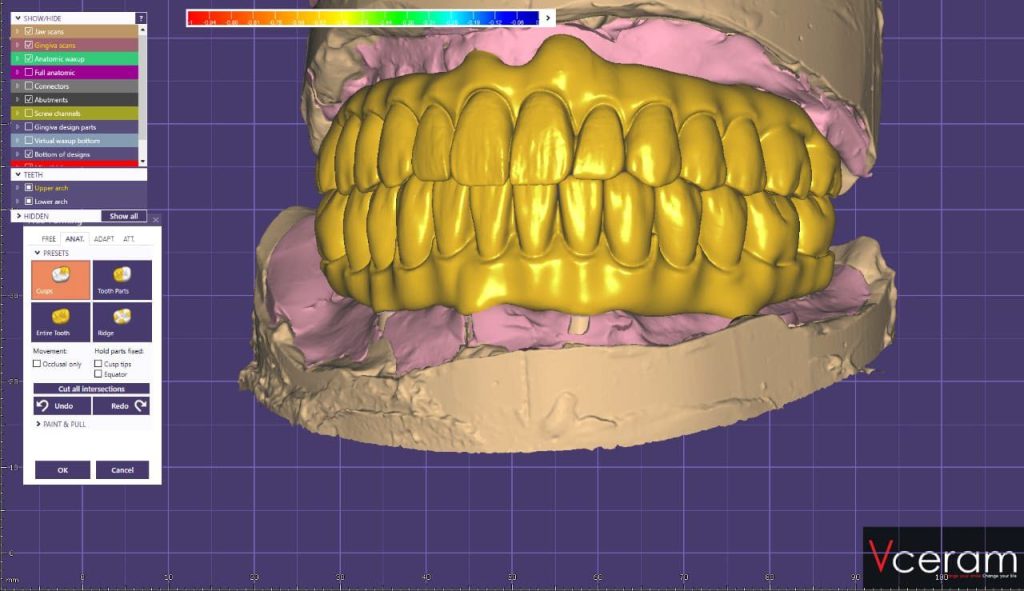

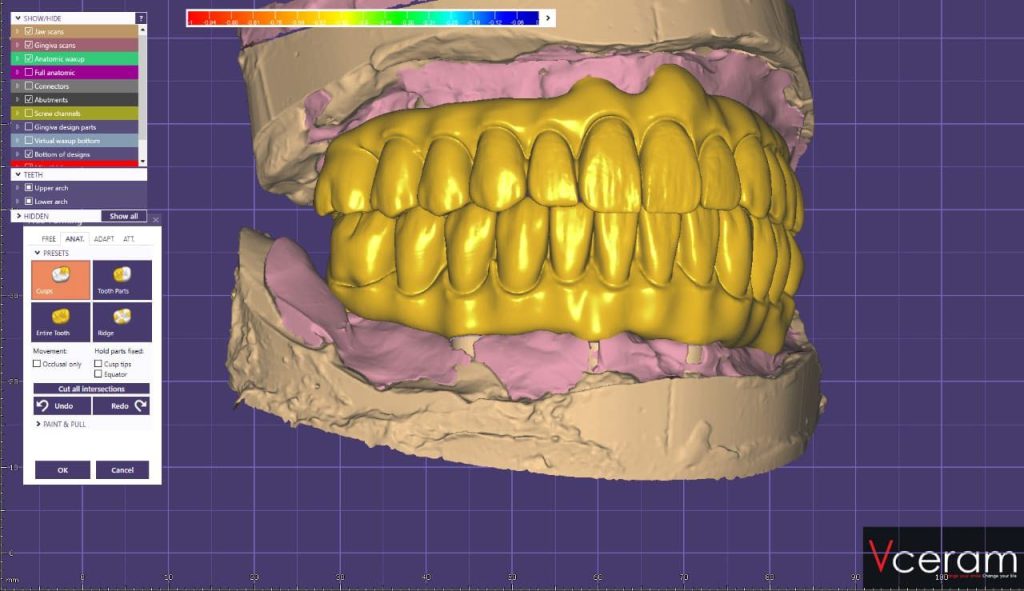

Digital Dentistry Revolution

Material Introduction

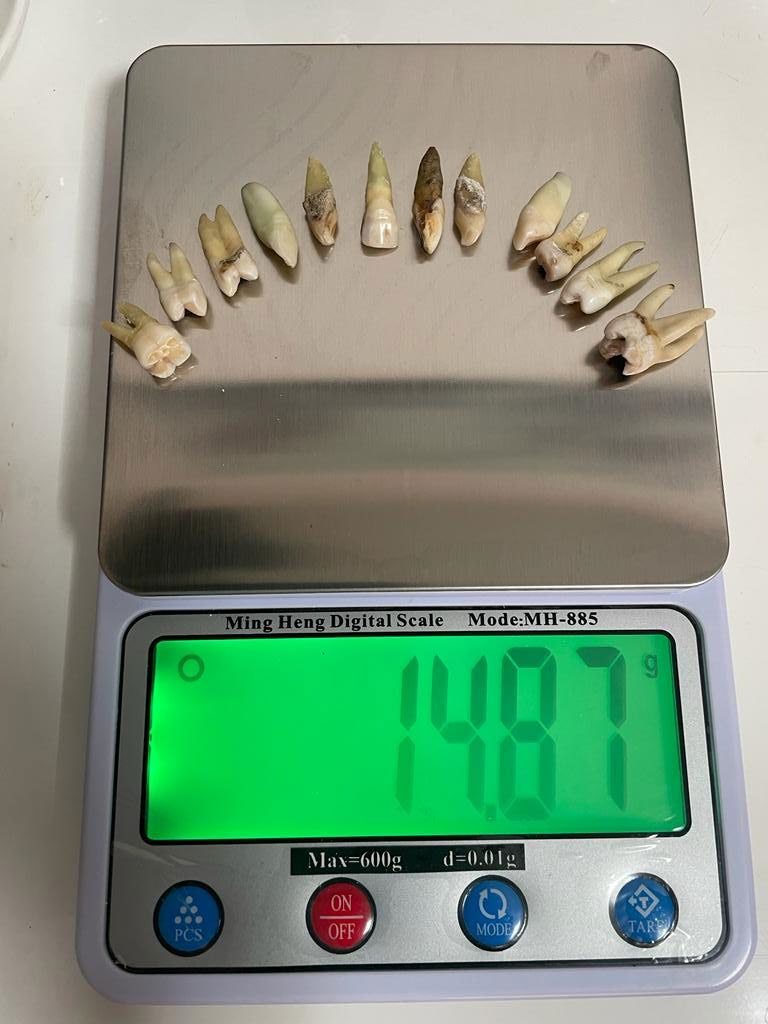

Type of loads applied on

dental implants :

Weight.

Force.

Time.

Formulas Available

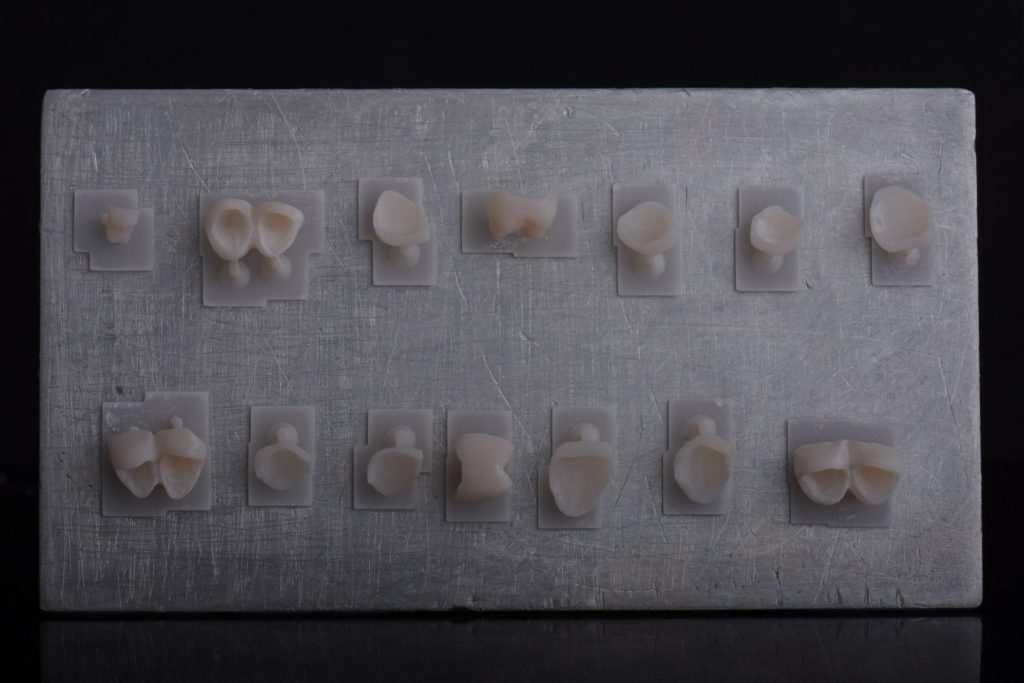

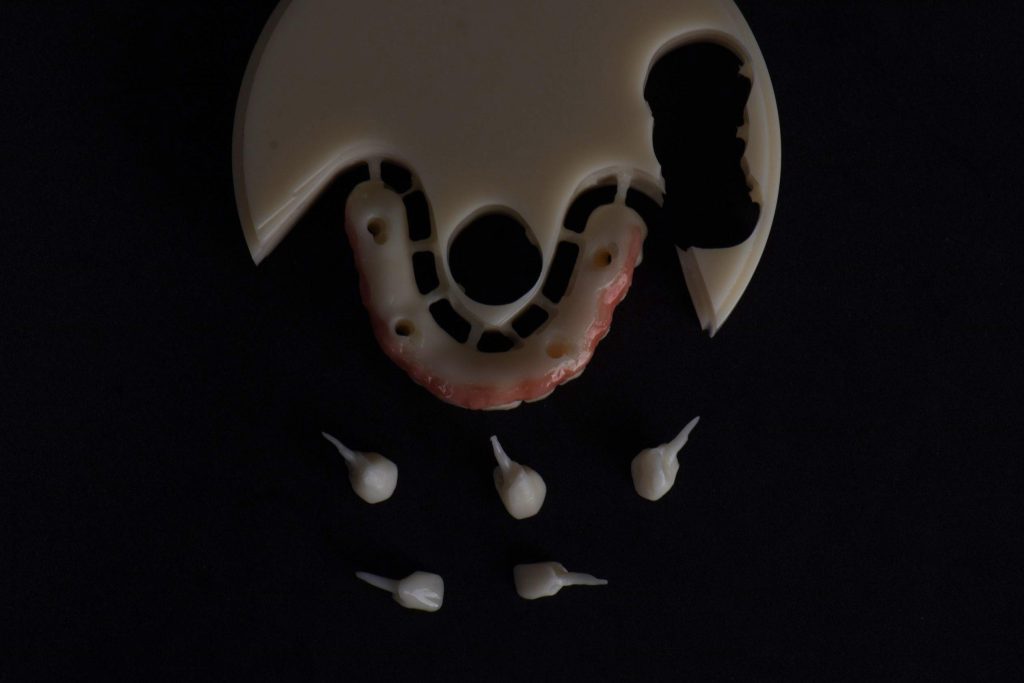

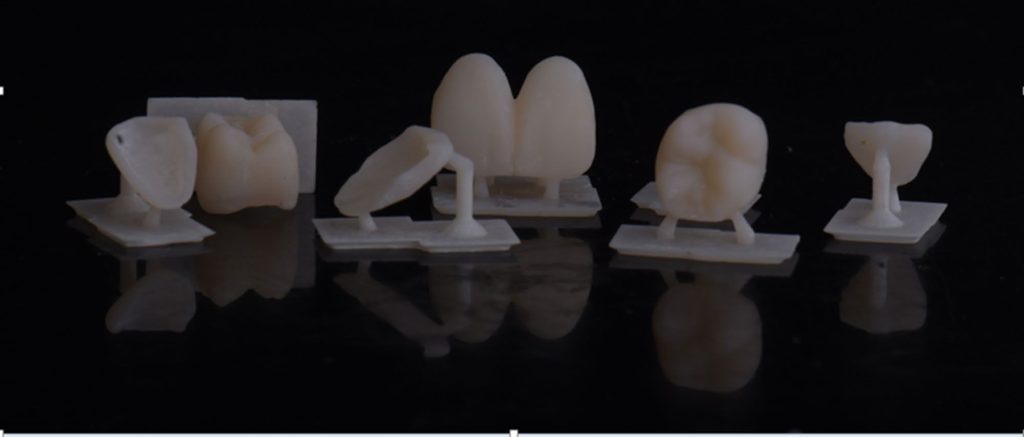

Discs

Nanoksa G Plus is composed of high performance polymers, designed to provide superior cutting performance and long-lasting durability. The disc is made of a special blend of polymers that are designed to resist wear and tear, while providing a smooth, consistent cut. The disc is designed to be used with a variety of dental tools, including drills, grinders, and polishers.

The disc is also designed to be used with a variety of materials, including metal, ceramic, and composite materials. The disc is designed to provide a precise, consistent cut, while reducing vibration and noise. The disc is also designed to be easy to use and maintain, with a long-lasting life.

Nanoksa G-Plus

Strength

Aesthetics

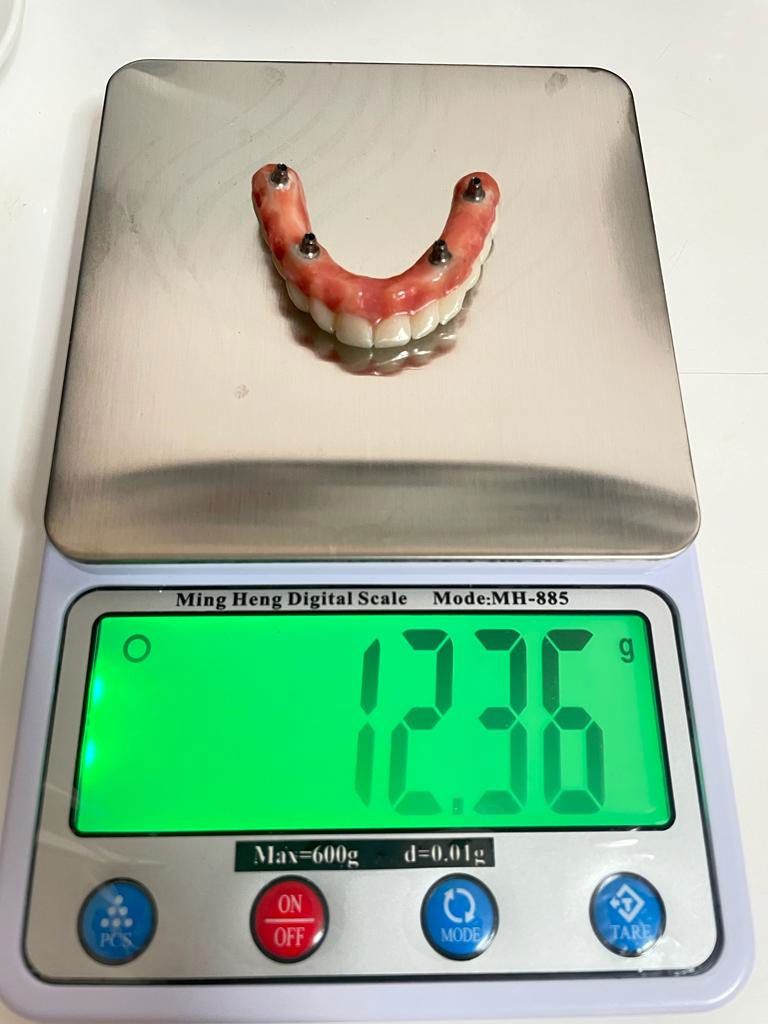

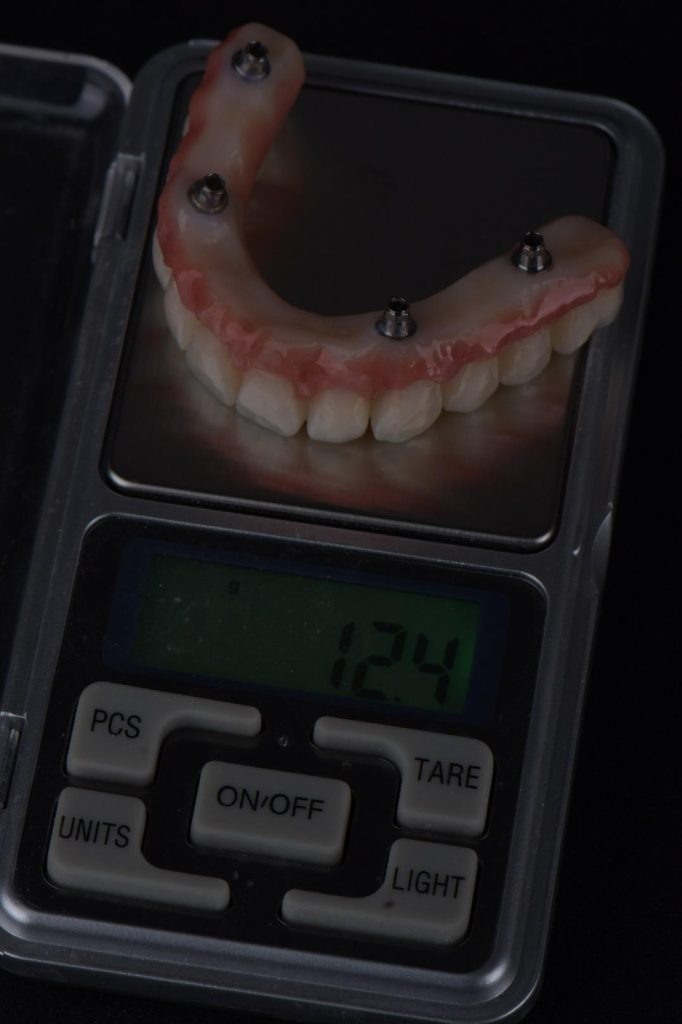

Weight mimics natural teeth

Bacterial accumulation prevention

color mimics natural teeth

Bonding to surface

Specs

1-Available Formulas :

-Liquid : Resin

-Solid: Discs

2-Material Composition :

High performance polymers filled with Nano-Zirconia and Carbon for the production of

permanent restorations on dental implants.

3-Strength characteristics :

Absorption ISO 1047 ug/mm ³ 4.9

Solubility ISO 1047 ug/mm³ < 0.1

Tensile test maximum load ISO 178 N 294

Breaking load ISO 178 N 237

Tensile test maximum load ISO 527 N 3274

Breaking load ISO 527 N 2639

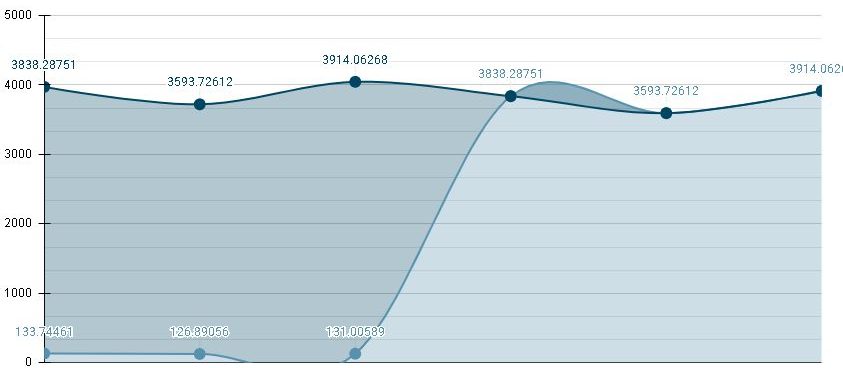

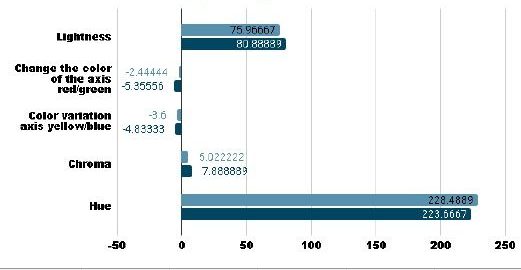

TESTS OF COLOR STABILITY

ΔECIELAB = (∆L* 2 + ∆a* 2 + ∆b* 2 ) ½

Where: L* = lightness (0-100), a* = (change the color of the axis red/green) and b* = (color variation axis yellow/blue )

[ Johnston WM. Color measurement in dentistry. J Dent 2009;37 Suppl 1:e2-6.]

TESTS OF COLOR STABILITY

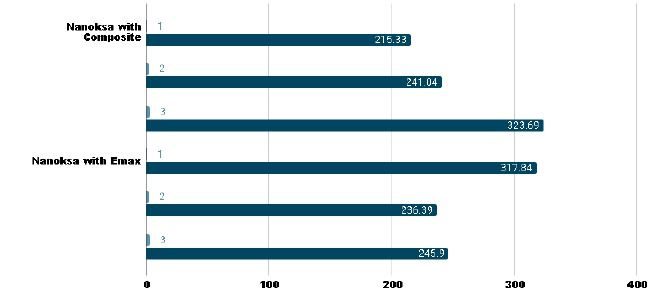

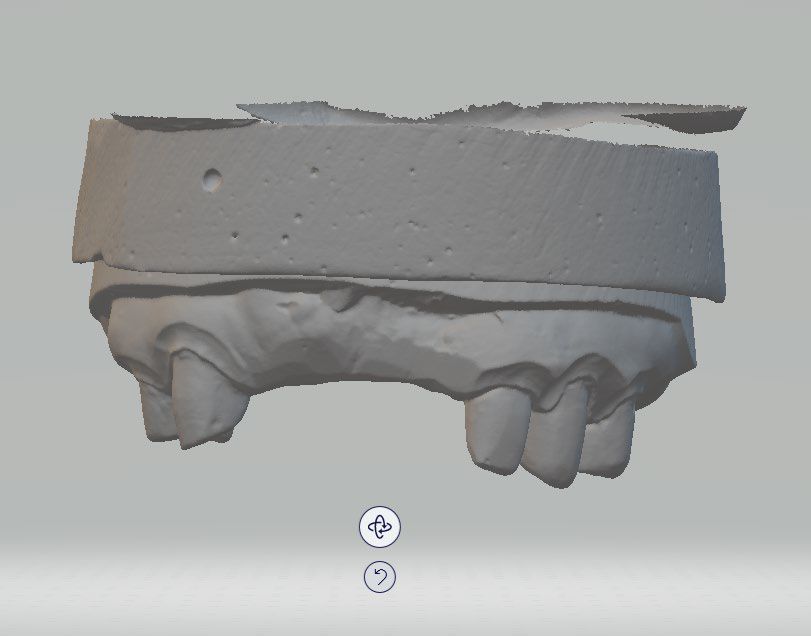

TESTS OF BONDING STREGHNTH

Test procedure

All samples were individually mounted on a computer controlled materials testing machine (Model 3345;

Instron Industrial Products, Norwood, MA, USA) with a loadcell of 5 kN and data were recorded using

computer software (Instron® Bluehill Lite Software). Samples were secured to the lower fixed

compartment of testing machine by tightening screws. Fracture resistance test was done by

compressive mode of load applied at 135o angle (through fixing the sample in specially designed 45o

angle jig) at incisal part of palatal surface using a metallic rod with round tip (3.4 mm diameter)

attached to the upper movable compartment of testing machine traveling at cross-head speed of

1mm/min with tin foil sheet in-between to achieve homogenous stress distribution and minimization of

the transmission of local force peaks.. The load at failure manifested by an audible crack and confirmed

by a sharp drop at load-deflection curve recorded using computer software (Bluehill Lite Software

Instron® Instruments). The load required to fracture was recorded in Newton

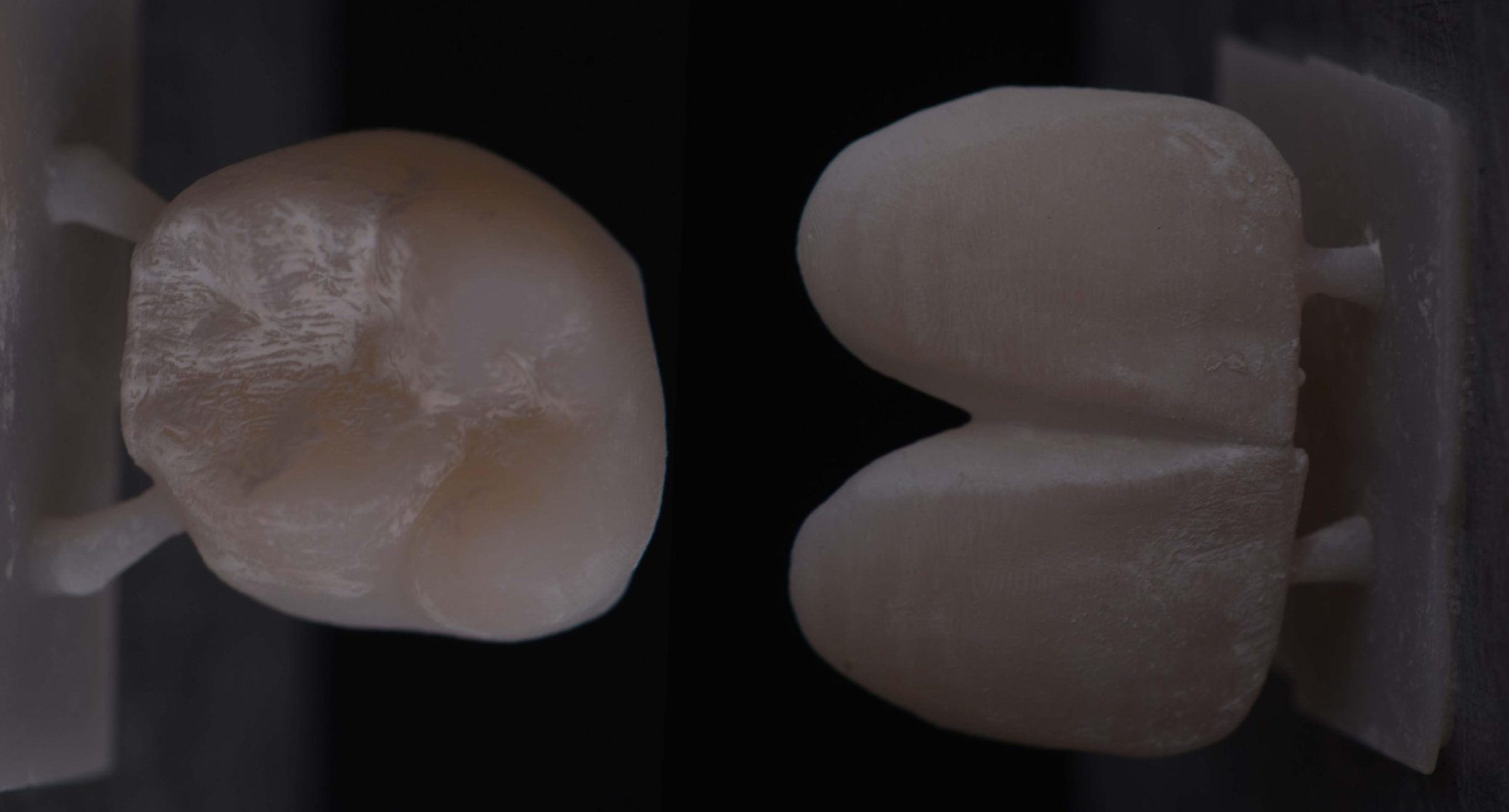

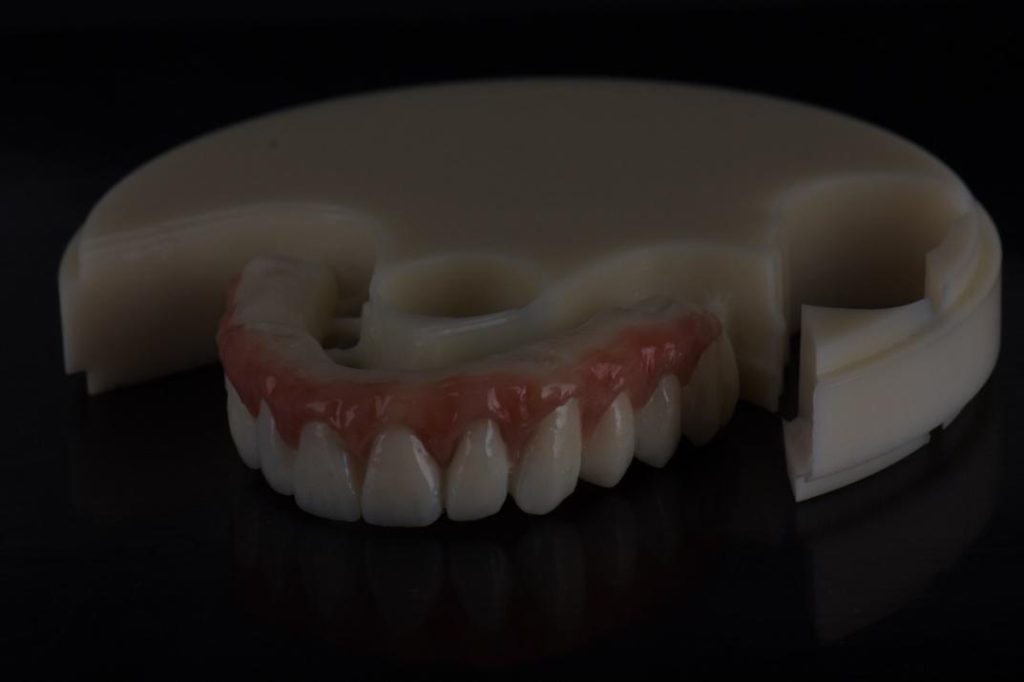

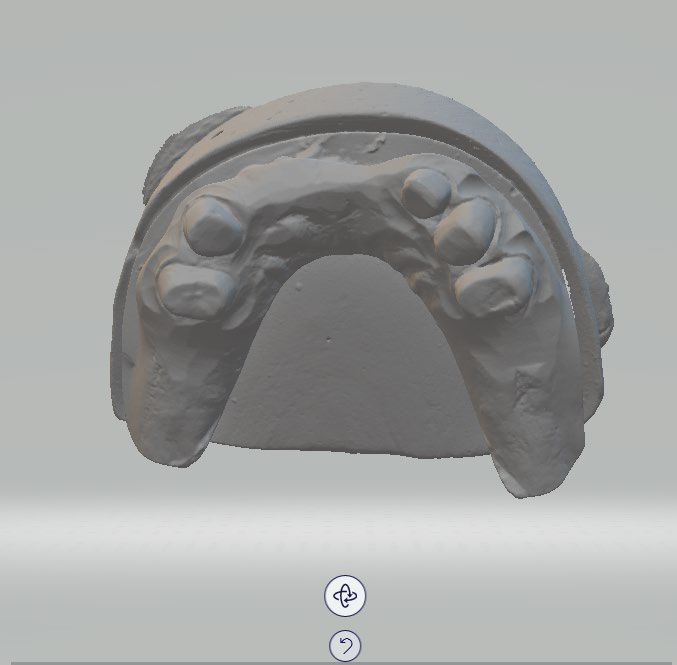

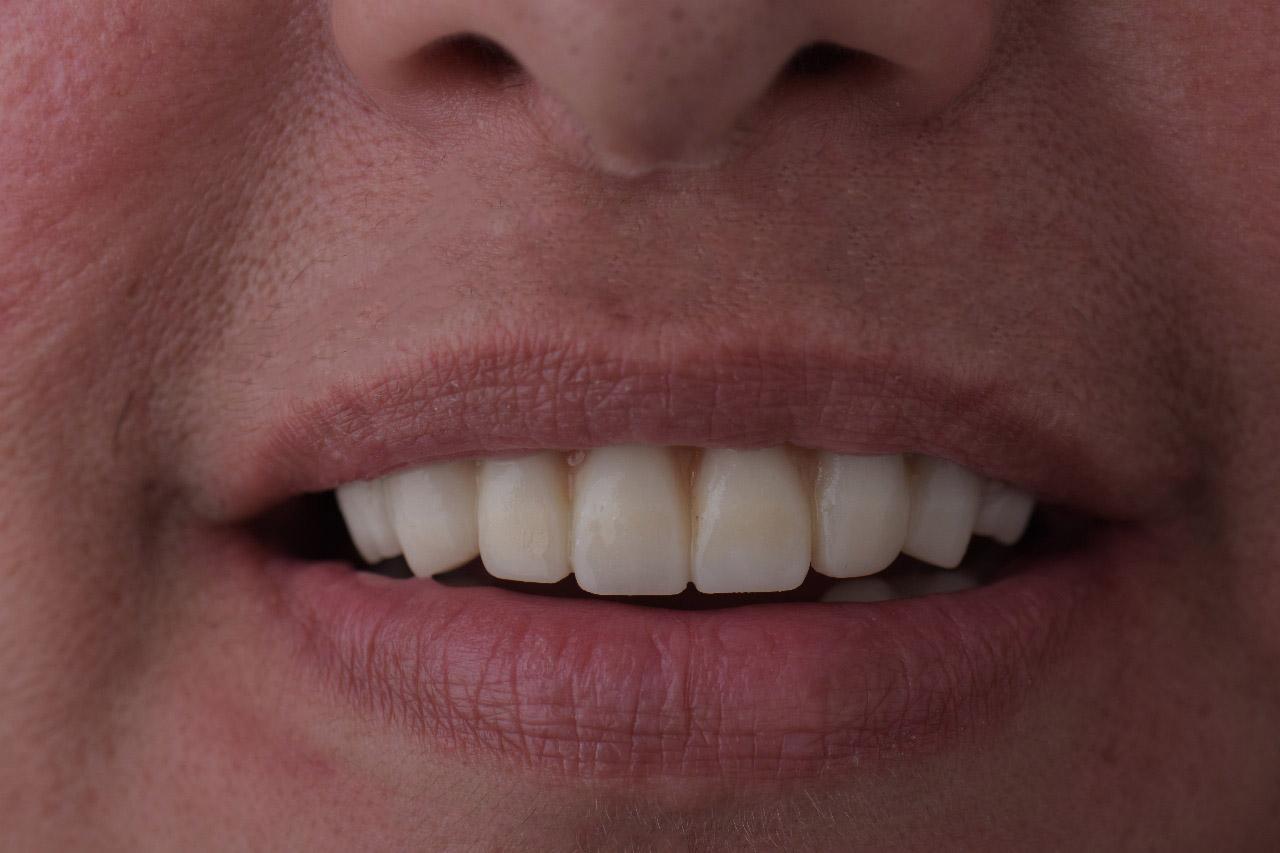

1- PROGRESSIVE AESTHETICS

2- Light weight mimics natural teeth.

3- Zirconia VS Nanoksa G Plus

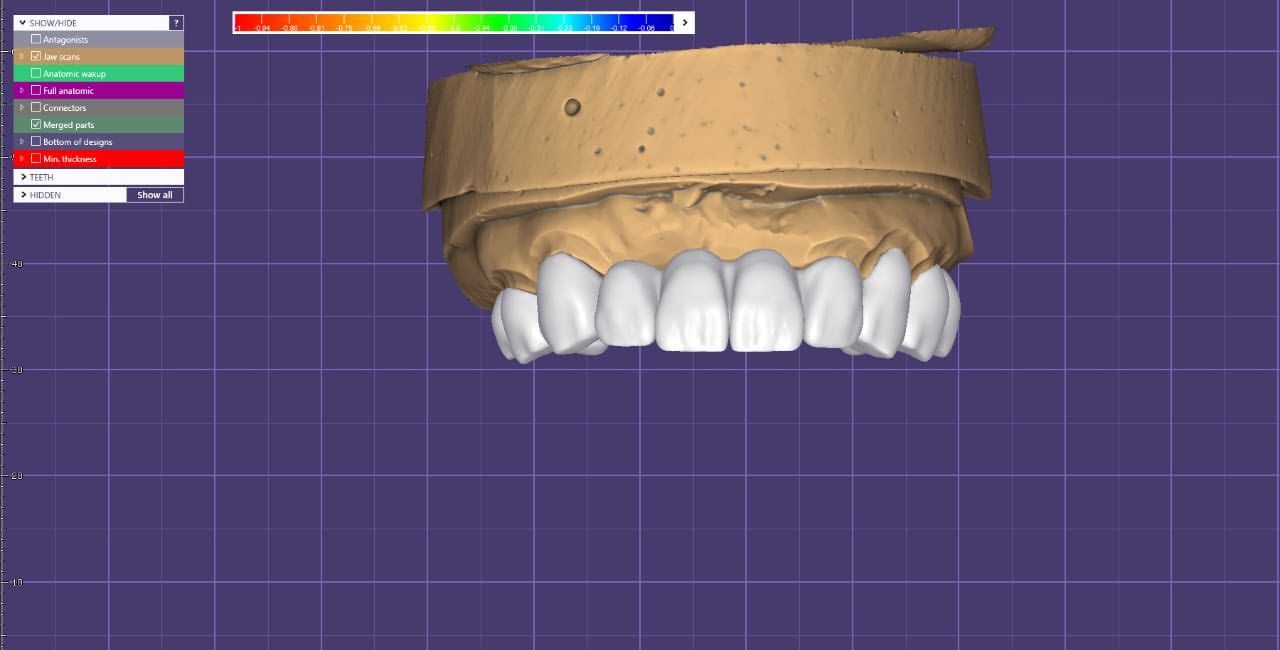

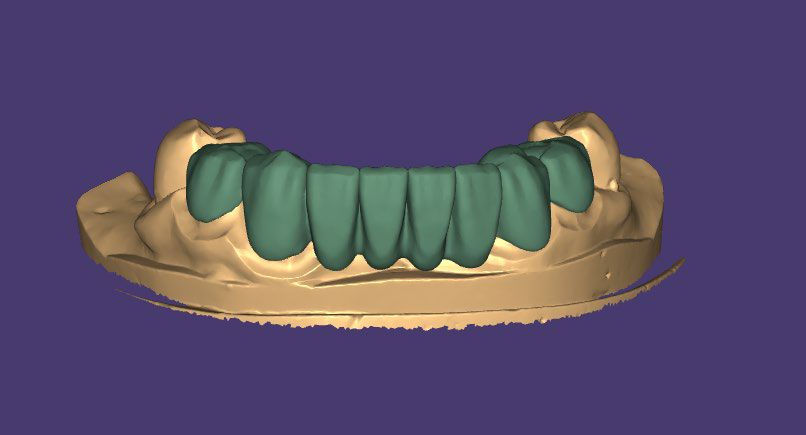

One step manufacturing

4-Incredible strength

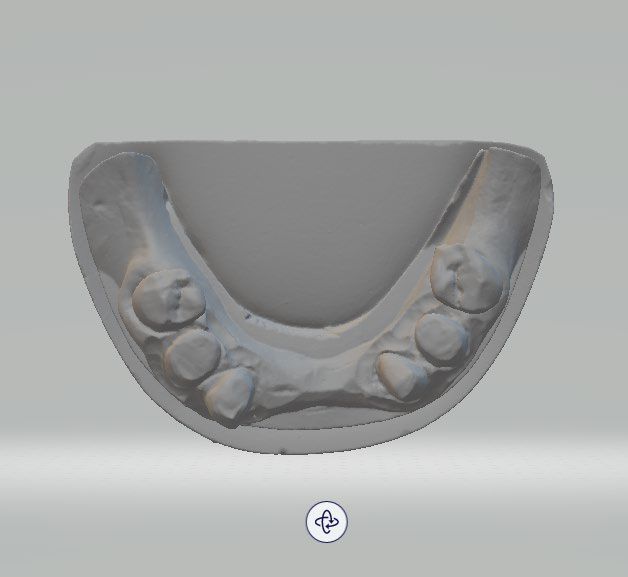

A 59 years old diabetic comes with a complain of mobile teeth and needing to restore anterior teeth and a masticatory function, without using implants, So we resorted it with a 3.8 gm bridge for upper and 4 gm for lower

Staining Technique

Layering Technique

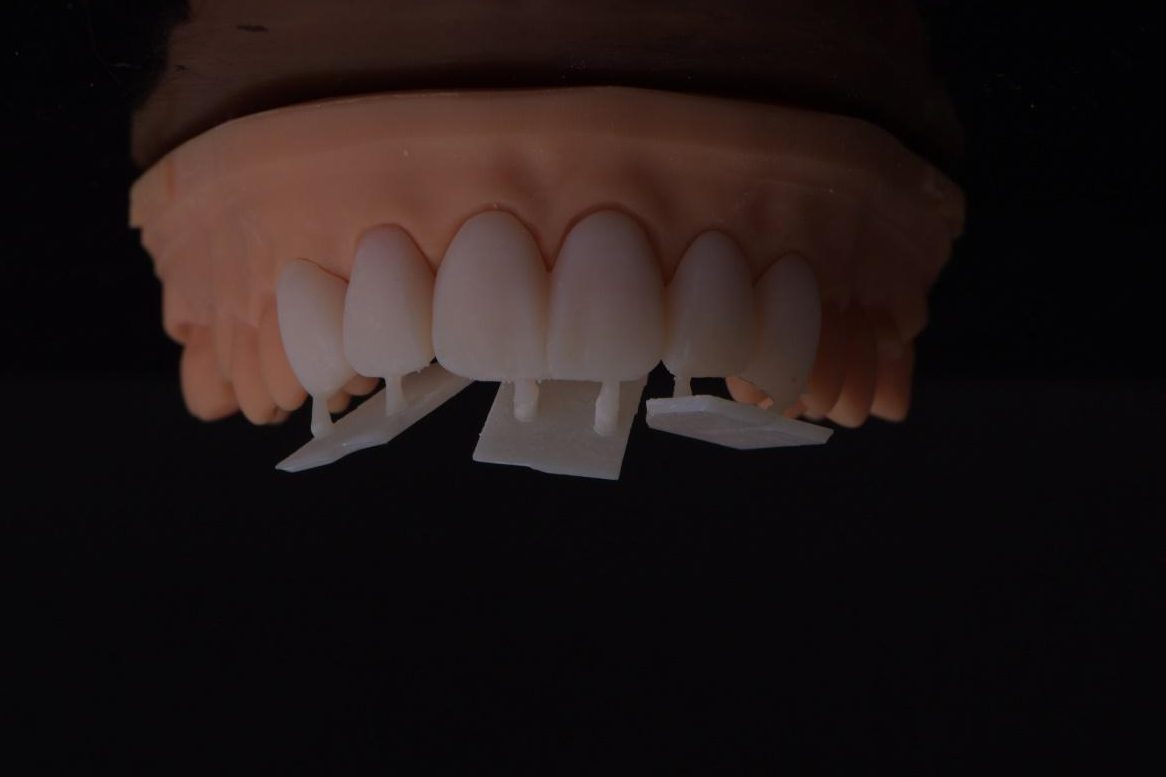

Cosmetics and fixed restorations

Formulas Available

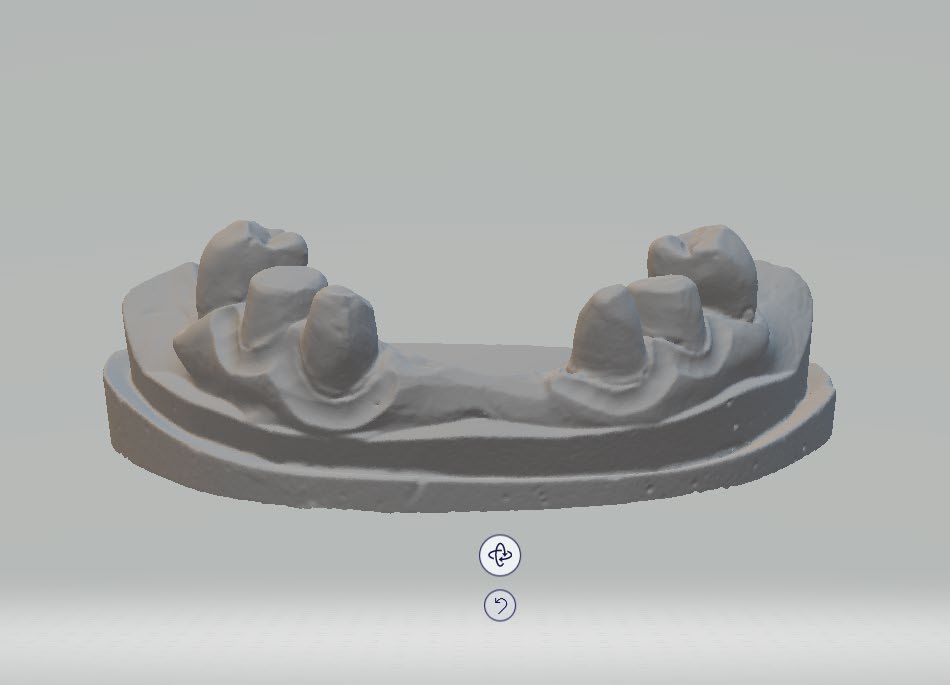

RESIN

As a result of modern technology, the resin utilized to

impregnate the fibers has exceptional strength

properties. It was necessary to develop a resin with

high performance and high biocompatibility of plant

origin for use in the oral cavity, which we named

Nanoksa G Plus Resin. Nanoksa G Plus Resin achieved

values of 100% biocompatibility in tests conducted in

accredited research laboratories.Due to its durability,

mechanical stability, and micro-mechanical elasticity

(shock absorption), Nanoksa G Plus provides a crucial

option for implant-prosthesis works.

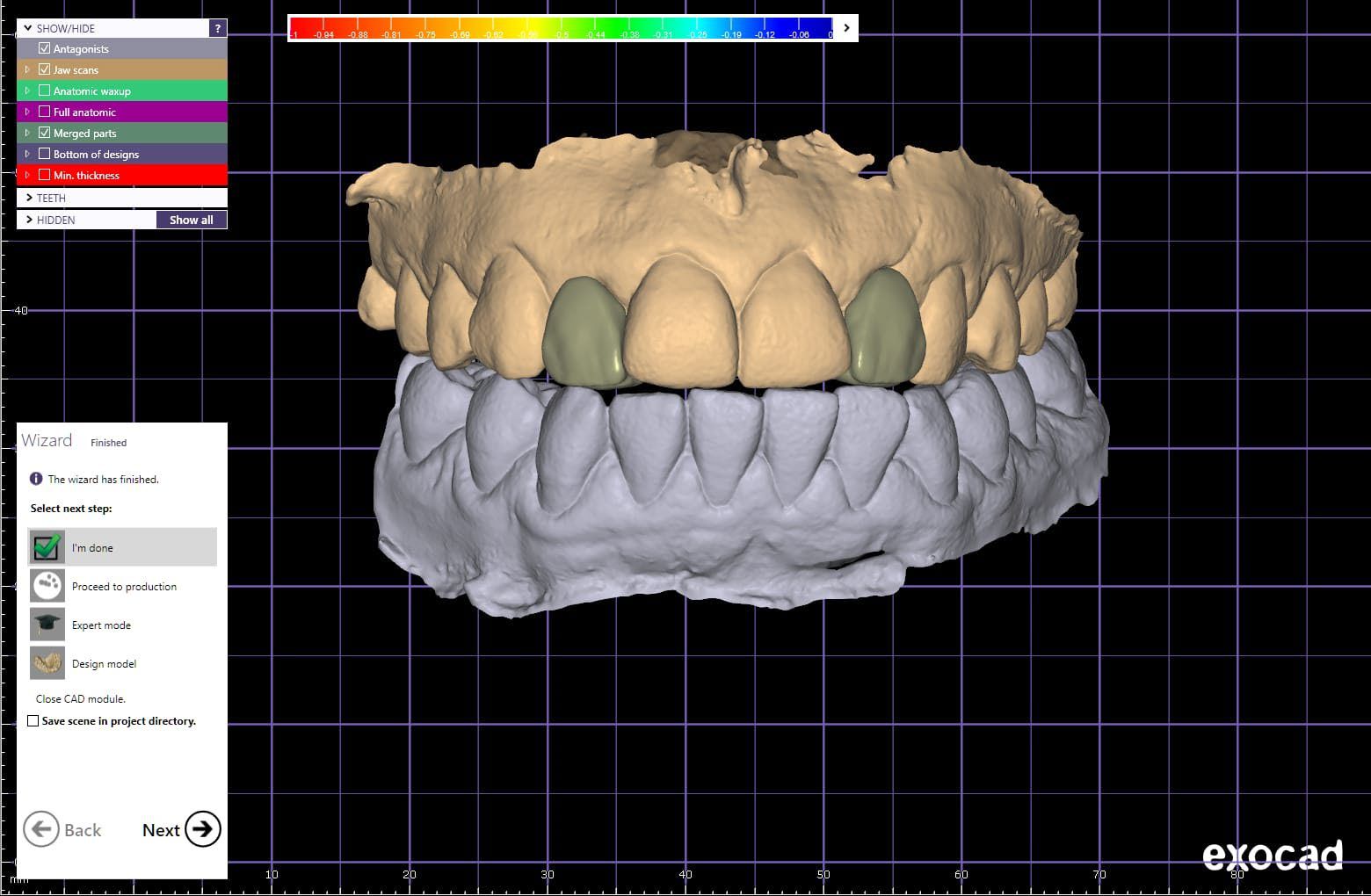

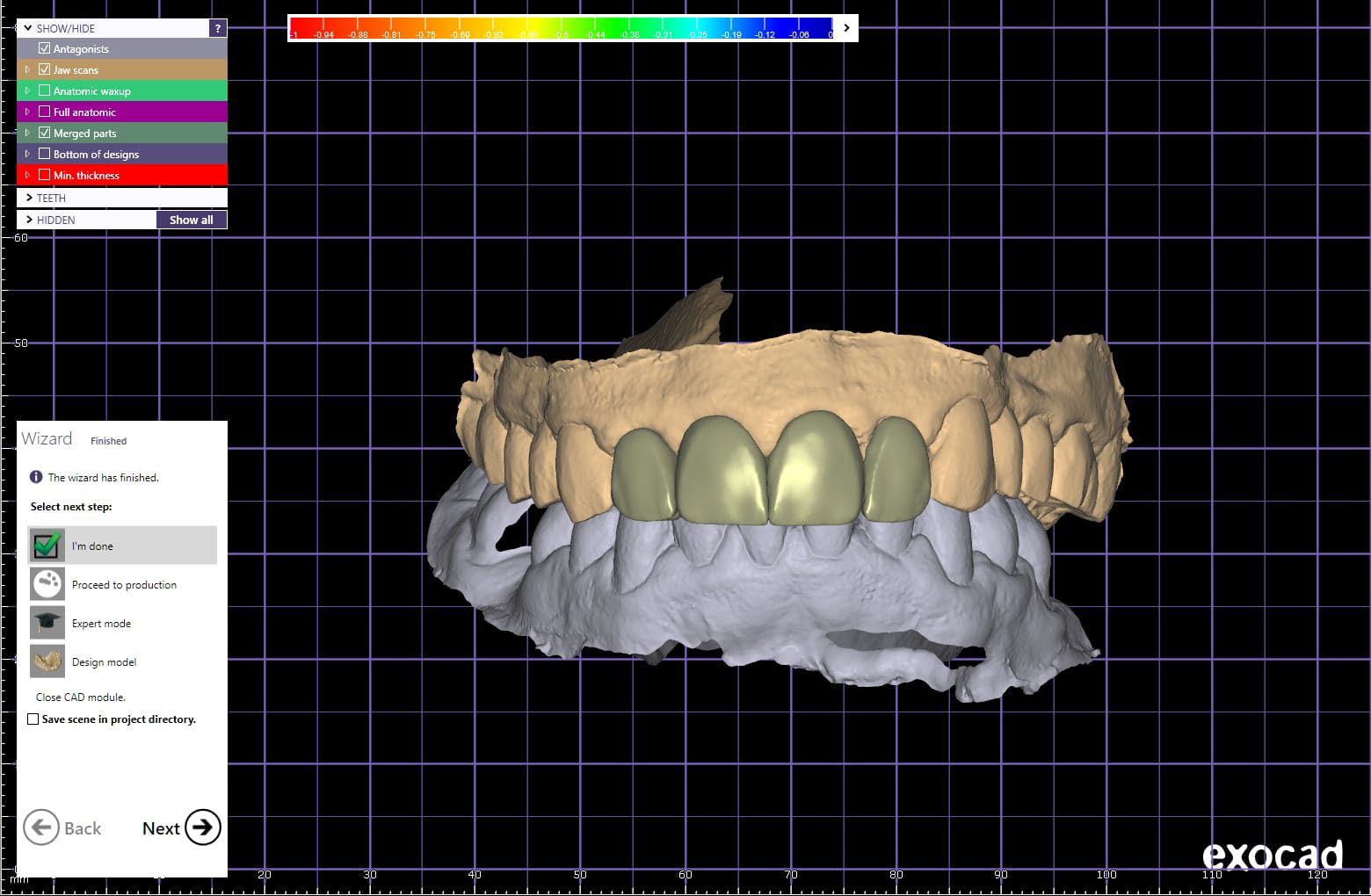

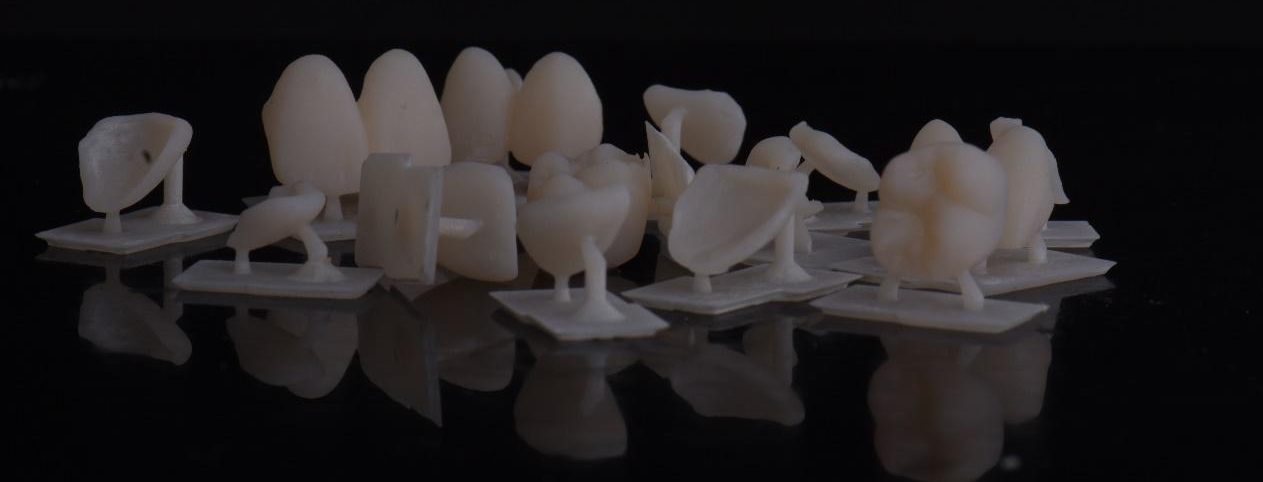

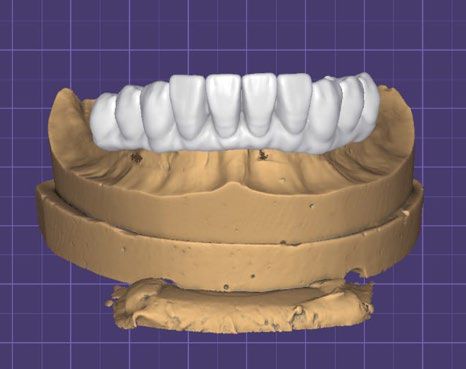

One step manufacturing

Get 30 units in 60 mins

Ease of manufacturing

Direct Printed Veneers